M-90 ER70S-G

Features

- Good Performance

- High Deposition

- Good Bead Appearance

Application

Pipes, Shipbuilding, Automotive, Machinery

Classification

AWS/A5.18/ ASME SFA5.18

ER70S-G

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.07 | 0.83 | 1.43 | - | - | - | - | - |

Mechanical Properties

| Y.S | T.S | EL | Temp. | CVN-Impact Value |

| N/mm2 (lbs/in 2) | N/mm2 (lbs/in 2) | (%) | oC (oF) | J (ft lbs) |

| 460 (66,700) | 530 (76,900) | 27 | -20 (-4) | 36(27) |

Welding Parameters

| DIAMETER (mm) | 1.6 | 2.4 |

| LENGTH (mm) | 1000 | 1000 |

| CURRENT (amps) | - | - |

Current

DC –

Gas

Ar

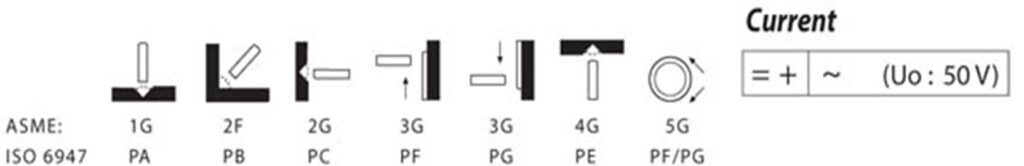

Welding Positions

M-90 ER70S-6

Features

- Good Performance

- High Deposition

- Good Bead Appearance

Application

Pipes, Shipbuilding, Automotive, Machinery

Classification

AWS/A5.18/ ASME SFA5.18

ER70S-6

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.07 | 0.85 | 1.5 | - | - | - | - | - |

Mechanical Properties

| Y.S | T.S | EL | Temp. | CVN-Impact Value |

| N/mm2 (lbs/in 2) | N/mm2 (lbs/in 2) | (%) | oC (oF) | J (ft lbs) |

| 450 (65,300) | 520 (75,500) | 28 | -20 (-4) | 180(132) |

Welding Parameters

| DIAMETER (mm) | 1.6 | 2.4 |

| LENGTH (mm) | 1000 | 1000 |

| CURRENT (amps) | - | - |

Current

DC –

Gas

Ar

Welding Positions

M-90 ER308

Features

- Resistance to crack

- High Efficiency

- Resistance to corrosion

Application

Steel Structure-oil, Textile Industries, Nuclear Reaction

Classification

A5.9/ ASME SFA5.9 ER308

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.04 | 0.41 | 1.75 | - | - | 19.9 | 9.8 | - |

Mechanical Properties

| Y.S | T.S | EL | Temp. | CVN-Impact Value |

| N/mm2 (lbs/in 2) | N/mm2 (lbs/in 2) | (%) | oC (oF) | J (ft lbs) |

| - | 610 (88,500) | 40 | 0 (32) | 130(95) |

Welding Parameters

| DIAMETER (mm) | 1.6 | 2.4 |

| LENGTH (mm) | 1000 | 1000 |

| CURRENT (amps) | 50-70 | 70-1000 |

Current

DC –

Gas

Ar

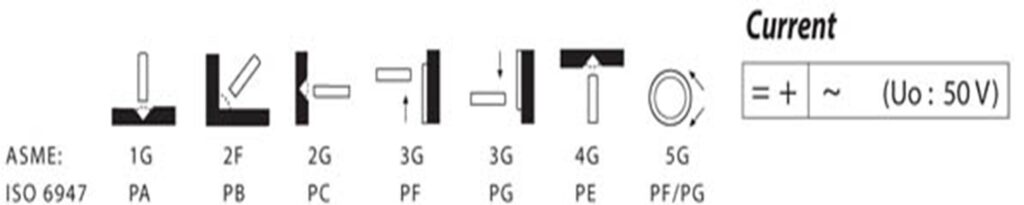

Welding Positions

M-90 ER308L

Features

- Resistance to crack

- High Efficiency

- Resistance to corrosion

Application

Designed for welding root passes in grooves with root opening. High corrosion resistance in oxidizing environments.

Classification

AWS/A5.9/ ASME SFA5.9

ER308L

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.02 | 0.32 | 1.70 | - | - | 20.0 | 10.1 | - |

Mechanical Properties

| Y.S | T.S | EL | Temp. | CVN-Impact Value |

| N/mm2 (lbs/in 2) | N/mm2 (lbs/in 2) | (%) | oC (oF) | J (ft lbs) |

| - | 600 (87,000) | 41 | 0 (32) | 110(81) |

Welding Parameters

| DIAMETER (mm) | 1.6 | 2.4 |

| LENGTH (mm) | 1000 | 1000 |

| CURRENT (amps) | - | - |

Current

DC –

Gas

Ar

Welding Positions

M-90 ER316L

Features

- Excellent crack resistance

- Excellent resistance to heat

- Excellent arc stability and bead wetting

Application

- Excellent crack resistance

- Excellent resistance to heat

- Excellent arc stability and bead wetting

Classification

A5.9/ ASME SFA5.9 ER316L

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.02 | 0.38 | 1.85 | - | - | 18.8 | 12.4 | 2.5 |

Mechanical Properties

| Y.S | T.S | EL | Temp. | CVN-Impact Value |

| N/mm2 (lbs/in 2) | N/mm2 (lbs/in 2) | (%) | oC (oF) | J (ft lbs) |

| - | 570 (82,700) | 44 | 0 (32) | 104(103) |

Welding Parameters

| DIAMETER (mm) | 1.6 | 2.4 |

| LENGTH (mm) | 1000 | 1000 |

| CURRENT (amps) | - | - |

Current

DC –

Gas

Ar

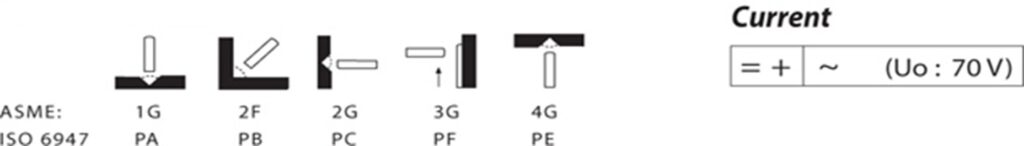

Welding Positions

M-90 ER4043

Features

- Good fluidity and less crack sensitivity

- Good corrosion resistance typically used as filler material for welding of aluminum parts

Application

- Welding filler wire

- Spray and flame metallizing wire

Classification

A5.10/ASME SFA A5.10 ER4043

Chemical Compositions

| Al | Be | Mn | Cu | Mg | Si | Zn | Ti |

| Remainder | 0.0008 | 0.05 | 0.30 | 0.05 | 5.0 | 0.10 | 0.15 |

Mechanical Properties

| T.S | Y.S |

| MPa | MPa |

| 195 | 170 |

Welding Parameters

| DIAMETER (mm) | 1.6 | 2.4 | 3.2 |

| LENGTH (mm) | 1000 | 1000 | 1000 |

| CURRENT (amps) | 50-70 | 70-100 | 100-150 |

Welding Positions

M-90 ER5356

Features

- Good fluidity and less crack sensitivity

- Good corrosion resistance typically used as filler material for welding of aluminum parts

Application

- Welding filler wire

- Spray and flame metallizing wire

Classification

A5.10/ASME SFA A5.10ER5356

Chemical Compositions

| Al | Be | Mn | Cu | Mg | Si | Zn | Ti |

| Remainder | 0.0008 | 0.05 | 0.10 | 0.05 | 0.25 | 0.10 | 0.15 |

Mechanical Properties

| T.S | Y.S |

| MPa | MPa |

| 290 | 198 |

Welding Parameters

| DIAMETER (mm) | 1.6 | 2.4 | 3.2 |

| LENGTH (mm) | 1000 | 1000 | 1000 |

| CURRENT (amps) | 50-70 | 70-100 | 100-150 |