M-90 E308-16

Features

Features

- Good creep resistance

- Service temperature up to 350⁰C

- Easy to remove slag

- Low spatter

- Good bead appearance

Application

- Rutile-basic all position stainless steel electrode. Used for welding low-carbon stainless steels of the type aisi 304 in cases where maximum resistance to intergranular corrosion is required.

- For welding Titanium and Niobium stabilized stainless steels. Weld able on both AC and DC.

Classification

AWS/A5.4/ ASME SFA5.4 E308-16

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.05 | 0.80 | 1.0 | 0.03 | 0.029 | 20.0 | 9.9 | 2.5 |

Mechanical Properties

| Y.S | T.S | EL | Temp. | CVN-Impact Value |

| N/mm2 (lbs/in 2) | N/mm2 (lbs/in 2) | (%) | oC (oF) | J (ft lbs) |

| 576 (23,500) | 576 (83,500) | 49.8 | -196(-321) | 36(27) |

Welding Parameters

| DIAMETER (mm) | 1.6 | 2 | 2.5 | 3.2 | 4 | 5 |

| LENGTH (mm) | 300 | 300 | 350 | 350 | 350 | 350 |

| CURRENT (amps) | 20-55 | 25-55 | 50-85 | 70-110 | 95-145 | 135-190 |

Current

AC or DC +-

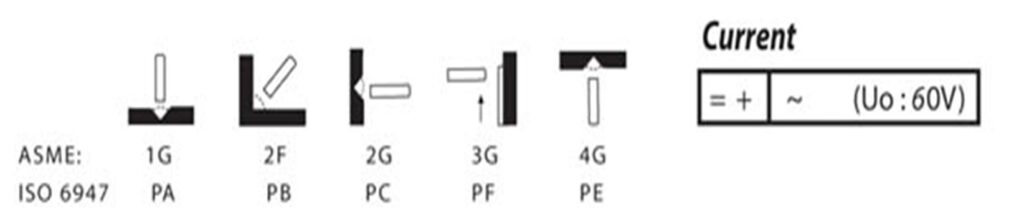

Welding Positions

M-90 E308L-16

Features

Features

- Good resistance to corrosion and oxidizing environments

- Easy to remove slag

- Good bead appearance

- High moisture resistance (17Type)

Application

- Rutile-basic coated electrode for welding non stabilized and stabilized corrosion resistant austenitic Cr-Ni steels up to 350°C.

- Smooth metal transfer with both AC and DC. Weld metal beads exhibit fine ripple formation.

- Focused and stable arc with low spatter loss.

- Self-detaching slag.

- Moisture resistant formulation producing welds free from porosity.

Classification

A5.4/ ASME SFA5.4 E308L-16

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.02 | 0.80 | 0.75 | 0.03 | 0.029 | 18.9 | 9.9 | 2.5 |

Mechanical Properties

| T.S | EL |

| N/mm2 (lbs/in 2) | (%) |

| 562 (81,600) | 47 |

Welding Parameters

| DIAMETER (mm) | 1.6 | 2 | 2.5 | 3.2 | 4 | 5 |

| LENGTH (mm) | 300 | 300 | 350 | 350 | 350 | 350 |

| CURRENT (amps) | 20-55 | 25-55 | 50-85 | 70-110 | 95-145 | 135-190 |

Current

AC or DC +-

Welding Positions

M-90 E309-16

Features

Features

- Good resistance to heat and corrosion

- Easy to remove slag

- Low spatter

Application

- Rutile-basic coated low carbon all positions stainless steel electrode.

- Suitable for welding high alloyed corrosion resistant Cr-Ni-Mo steels, dissimilar steels (austenitic to ferritic steels). Deposition of austenitic cladding root runs.

- Focused and stable arc.

- Easy slag release.

Classification

A5.4/ ASME SFA5.4 E309.16

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.03 | 0.79 | 1.1 | 0.025 | 0.016 | 23.4 | 12.5 | 0.1 |

Mechanical Properties

| T.S | EL |

| N/mm2 (lbs/in 2) | (%) |

| 579 (84,100) | 38.6 |

Welding Parameters

| DIAMETER (mm) | 2.5 | 3.2 |

| LENGTH (mm) | 350 | 350 |

| CURRENT (amps) | 50-85 | 70-100 |

Current

AC or DC +-

Welding Positions

M-90 E310-16

Features

Features

- Good heat resistance

- Good mechanical properties

- Martensite structure (all-weld metal)

- Easy to remove slag

Application

- Basic rutile coated, fully austenitic all position electrodes.

- Suitable for welding heat resistant Cr and Cr-Ni steels.

- Oxidation and scaling resistance up to 1200°C

Classification

A5.4/ ASME SFA5.4 E310.16

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.10 | 0.6 | 1.9 | 0.018 | 0.013 | 26.5 | 20.6 | - |

Mechanical Properties

| T.S | EL |

| N/mm2 (lbs/in 2) | (%) |

| 610 (88,400) | 35 |

Welding Parameters

| DIAMETER (mm) | 2.5 | 3.2 |

| LENGTH (mm) | 350 | 350 |

| CURRENT (amps) | 50-85 | 70-100 |

Current

AC or DC +-

Welding Positions

M-90 E312-16

Features

Features

- Good crack resistance

- Good mechanical properties

- Easy to remove slag

Application

- Buffer layer for build up

- Welding dissimilar needs

Classification

A5.4/ ASME SFA5.4 E312.16

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.10 | 0.45 | 1.4 | 0.018 | 0.013 | 28.5 | 9.6 | - |

Mechanical Properties

| T.S | EL |

| N/mm2 (lbs/in 2) | (%) |

| 803 (116,600) | 22.0 |

Welding Parameters

| DIAMETER (mm) | 2.5 | 3.2 |

| LENGTH (mm) | 300 | 350 |

| CURRENT (amps) | 45-80 | 65-100 |

Current

AC or DC +-

Welding Positions

M-90 E316-16

Features

Features

- Good resistance to corrosion and oxidizing environments

- Good heat resistance

- Low spatter

Application

- High recovery (170%) rutile coated electrode for welding austenitic stainless CR-Ni-MO steels

- Used whenever easy welding, smooth welding surfaces and a high deposition rates are required

Classification

A5.4/ ASME SFA5.4 E316-16

Chemical Compositions

| T.S | EL |

| N/mm2 (lbs/in 2) | (%) |

| 572 (83,100) | 40.8 |

Mechanical Properties

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.03 | 0.77 | 0.9 | 0.03 | 0.029 | 18.7 | 12.3 | 2.5 |

Welding Parameters

| DIAMETER (mm) | 2.5 | 3.2 |

| LENGTH (mm) | 350 | 350 |

| CURRENT (amps) | 50-85 | 70-100 |

Current

AC or DC +-

Welding Positions

M-90 E316L-16

Features

Features

- Good resistance to corrosion and oxidizing environments

- Good heat resistance

- Easy to remove flag

- High moisture resistance (17Type)

Application

- Rutile coated electrode for welding on stabilized corrosion resistant cr-ni-mo steels.

- Smooth metal transfer with both AC and DC.

- Weld metal beads exhibit fine ripple formation.

- Focused and stable arc with low spatter loss.

- Easy slag release.

- Moisture resistant formula producing welds free from porosity.

Classification

A5.4/ ASME SFA5.4 E316L-16

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.25 | 0.80 | 0.80 | 0.03 | 0.29 | 18.7 | 11.3 | 2.5 |

Mechanical Properties

| T.S | EL |

| N/mm2 (lbs/in 2) | (%) |

| 572 (83,100) | 40.8 |

Welding Parameters

| DIAMETER (mm) | 2.5 | 3.2 |

| LENGTH (mm) | 350 | 350 |

| CURRENT (amps) | 50-85 | 70-100 |

Current

AC or DC +-

Welding Positions

M-90 ER308

Features

Features

- Resistance to crack

- High efficiency

- Resistance to corrosion

Application

Steel Structure-oil, Textile Industries, Nuclear Reaction

Classification

A5.9/ ASME SFA5.9 ER308

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.04 | 0.41 | 1.75 | - | - | 19.9 | 9.8 | - |

Mechanical Properties

| Y.S | T.S | El | Temp | CVN-Impact Value |

| N/mm2 (lbs/in 2) | N/mm2 (lbs/in 2) | (%) | oC (oF) | J (ft lbs) |

| - | 610 (88,500) | 40 | 0 (32) | 130(95) |

Welding Parameters

| DIAMETER (mm) | 1.6 | 2.4 |

| LENGTH (mm) | 1000 | 1000 |

| CURRENT (amps) | 50-70 | 70-100 |

Current

DC –

Gas

Ar

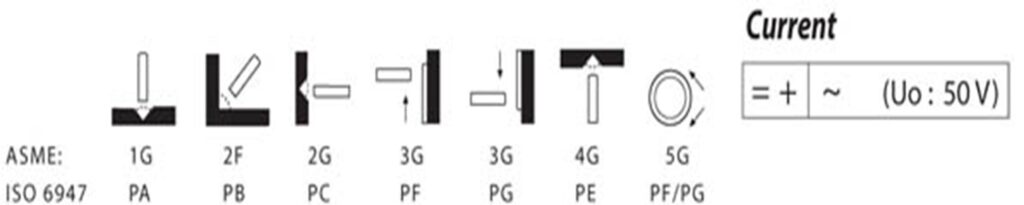

Welding Positions

M-90 ER308L

Features

Features

- Resistance to crack

- High efficiency

- Resistance to corrosion

Application

Designed for welding root passes in grooves with root opening. High corrosion resistance in oxidizing environments.

Classification

AWS/A5.9/ ASME SFA5.9 ER308L

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.02 | 0.32 | 1.70 | - | - | 20.0 | 10.1 | - |

Mechanical Properties

| Y.S | T.S | El | Temp | CVN-Impact Value |

| N/mm2 (lbs/in 2) | N/mm2 (lbs/in 2) | (%) | oC (oF) | J (ft lbs) |

| - | 600 (87,000) | 41 | 0 (32) | 110(81) |

Welding Parameters

| DIAMETER (mm) | 1.6 | 2.4 |

| LENGTH (mm) | 1000 | 1000 |

| CURRENT (amps) | - | - |

Current

DC –

Gas

Ar

Welding Positions

M-90 ER316L

Features

Features

- Excellent crack resistance

- Excellent resistance to heat

- Excellent arc stability and bead wetting

Application

- Excellent crack resistance

- Excellent resistance to heat

- Excellent arc stability and bead wetting

Classification

A5.9/ ASME SFA5.9 ER316L

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.02 | 0.38 | 1.85 | - | - | 18.8 | 12.4 | 2.5 |

Mechanical Properties

| Y.S | T.S | El | Temp | CVN-Impact Value |

| N/mm2 (lbs/in 2) | N/mm2 (lbs/in 2) | (%) | oC (oF) | J (ft lbs) |

| - | 570 (82,700) | 44 | 0 (32) | 104(103) |

Welding Parameters

| DIAMETER (mm) | 1.6 | 2.4 |

| LENGTH (mm) | 1000 | 1000 |

| CURRENT (amps) | - | - |

Current

DC –

Gas

Ar

Welding Positions

M-90 ER70S-6

Features

Features

- Good performance

- High deposition

- Good bead appearance

Application

Pipes, Shipbuilding, Automotive, Machinery

Classification

AWS/A5.18/ ASME SFA5.18 ER70S-6

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.07 | 0.85 | 1.5 | - | - | - | - | - |

Mechanical Properties

| Y.S | T.S | El | Temp | CVN-Impact Value |

| N/mm2 (lbs/in 2) | N/mm2 (lbs/in 2) | (%) | oC (oF) | J (ft lbs) |

| 450 (65,300) | 520 (75,500) | 28 | -20 (-4) | 180(132) |

Welding Parameters

| DIAMETER (mm) | 1.6 | 2.4 |

| LENGTH (mm) | 1000 | 1000 |

| CURRENT (amps) | - | - |

Current

DC –

Gas

Ar