M-90 ENi-CI

Features

Features

- High-strength arc-submerge welding wires in series

- High-strength copper-plating

- Common electrodes

Application

- Special electrode for depositing soft machinable metal on grey cast iron.

- Excellent for repairing casting defects in grey cast iron.

- Can join cast irons to steels, monels etc.

Classification

A5.15/ ASME SFA5.15 Eni-CI

Chemical Compositions

| C | Si | Mn | P | S | Fe | Ni | MO |

| 1.35 | 0.78 | 0.35 | 0.004 | 0.003 | 0.55 | 96.0 | - |

Hardness

| Hardness (HRB) |

| 77 |

Welding Parameters

| DIAMETER (mm) | 2.5 | 3.2 | 4 |

| LENGTH (mm) | 350 | 350 | 350 |

| CURRENT (amps) | 55-80 | 80-110 | 90-135 |

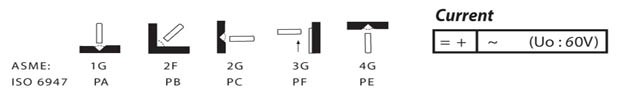

Current

AC or DC +-

Welding Positions

M-90 ENife-CI

Features

Features

- High impact toughness as low temperature

- Good arc & slag stability and hot cracking resistance

- Good productivity

Application

- Basic coated electrode which deposits a machinable nickel iron alloy weld.

- Designed for strength welding of high duty cast iron such as mechanite, malleable and spheroidal graphite and nodular irons.

- Welds high phosphorus castings.

- Typical components to be welded are machine bases, pump bodies, engine blocks, gears and transmission housings.

Classification

A5.15/ ASME SFA5.15 ENiFe-CI

Chemical Compositions

| C | Si | Mn | P | S | Fe | Ni | MO |

| 1.73 | 0.59 | 1.35 | 0.005 | 0.001 | 45.7 | 55.00 | - |

Hardness

| Hardness (HRB) |

| 90.0 |

Welding Parameters

| DIAMETER (mm) | 2.5 | 3.2 | 4 |

| LENGTH (mm) | 350 | 350 | 350 |

| CURRENT (amps) | 60-90 | 80-130 | 110-160 |

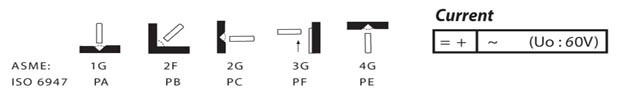

Current

AC or DC +-

Welding Positions

M-90 ESt

Features

Features

- Shielded metal arc welding of cast iron metal

- Non-machinable

- Semi machinable and non machinable types

Application

- Repairing of cast iron.

Classification

A5.15/ ASME SFA5.15 ESt

Chemical Compositions

| C | Si | Mn | P | S | CR | Fe | MO |

| 2.47 | 0.41 | 0.45 | 0.024 | 0.024 | 0.0 | 97.6 | - |

Hardness

| Hardness (HRB) |

| 450-510 |

Welding Parameters

| DIAMETER (mm) | 2.5 | 3.2 | 4 |

| LENGTH (mm) | 350 | 350 | 350 |

| CURRENT (amps) | 60-90 | 80-130 | 110-160 |

Current

AC or DC +-